A linear actuator is a mechanical device used to create linear motion, i.e., movement in a straight line, as opposed to rotary motion. These actuators are widely used in applications where controlled movement along a single axis is required. From industrial machinery and robotics to medical devices and home automation, linear actuators have become an integral part of numerous systems due to their precision, efficiency, and versatility.

How a Linear Actuator Works

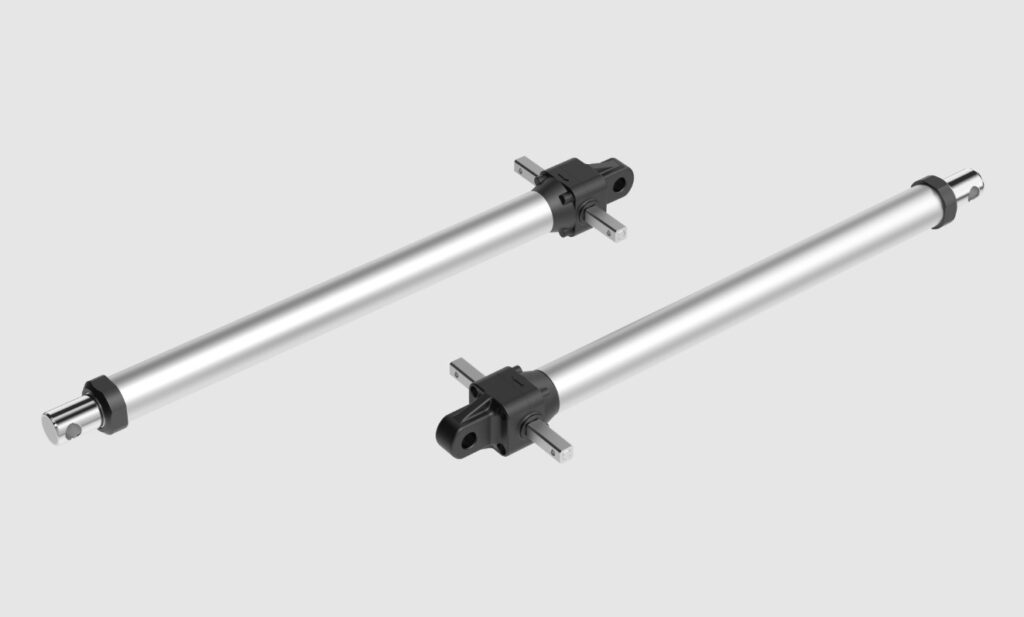

Linear actuators typically consist of a motor, a lead screw or ball screw, and a housing that supports these components. When the actuator is powered on, the motor drives the screw mechanism, which converts rotary motion into linear motion. The motor may be electric, pneumatic, or hydraulic, depending on the specific application and power requirements. The lead screw or ball screw then moves the attached load, either extending or retracting, depending on the direction of the motor’s movement.

Applications of Linear Actuators

1. Industrial Automation

In industrial settings, linear actuators are used for a wide range of tasks such as material handling, positioning machinery, and assembly lines. Their ability to provide precise, repeatable movements makes them ideal for automating processes and reducing labor costs.

2. Medical Devices

Linear actuators are used in medical equipment such as hospital beds, patient lifts, and wheelchairs. These actuators allow for easy adjustments in height, angle, and position, improving patient comfort and convenience.

3. Robotics

Linear actuators are a key component in many robotic systems, where they are used to move limbs, grippers, and other robotic parts. Their ability to provide smooth, controlled motion is essential for the functionality of robots in tasks like assembly, testing, and surgery.

4. Automotive and Aerospace

In the automotive and aerospace industries, linear actuators are used to adjust seats, windows, and doors, as well as in landing gear and other components that require precise control.

5. Home Automation

Linear actuators are used in home automation systems, including motorized windows, adjustable beds, and furniture. They allow users to control movement remotely, adding convenience and comfort to daily life.

6. Agriculture

In agriculture, linear actuators are used for automated systems like greenhouse venting, crop irrigation, and harvesting equipment. Their ability to adjust equipment based on environmental conditions improves productivity and efficiency.sumption, making them an environmentally friendly option for many applications.

Factors to Consider When Choosing a Linear Actuator

1. Load Capacity

It’s essential to select a linear actuator that can handle the weight of the object or load it will move. Overloading an actuator can cause it to fail prematurely.

2. Speed and Stroke Length

The speed at which the actuator moves and the length of its stroke (the distance it can extend or retract) must be matched to the requirements of the application. For example, a faster stroke may be required for automation systems, while slower, more controlled motion may be needed in medical devices.

3. Power Source

Consider the power requirements of the actuator. Electric actuators are commonly used in controlled environments, while pneumatic or hydraulic actuators are better suited for high-force applications.

4. Environment and Conditions

Depending on the environment, you may need an actuator that is resistant to moisture, dust, or extreme temperatures. Some actuators are designed with special coatings or enclosures to protect them from the elements.

5. Control Method

The control system for the actuator should be compatible with the overall system. Many actuators come with built-in sensors and controllers, but they can also be integrated into more complex control systems if needed.

Conclusion

Linear actuators are a fundamental component of modern motion control systems, offering precision, versatility, and reliability across a wide range of industries. Whether for industrial automation, medical equipment, or home automation, their ability to provide smooth, controlled linear motion makes them an indispensable tool. With continued advancements in technology, linear actuators will remain at the forefront of innovation, driving efficiencies and enabling new applications.

For high-quality, durable, and efficient linear actuators, JIECANG offers cutting-edge solutions that meet the diverse needs of customers across industries. With a commitment to performance and reliability, JIECANG’s products ensure precise motion control for a variety of applications, providing the reliability and functionality required for long-term use.

For more information about Linear Actuator, please visit our official website https://www.jiecang.com/